SolidCAM 2023 for SOLIDWORKS Free Download

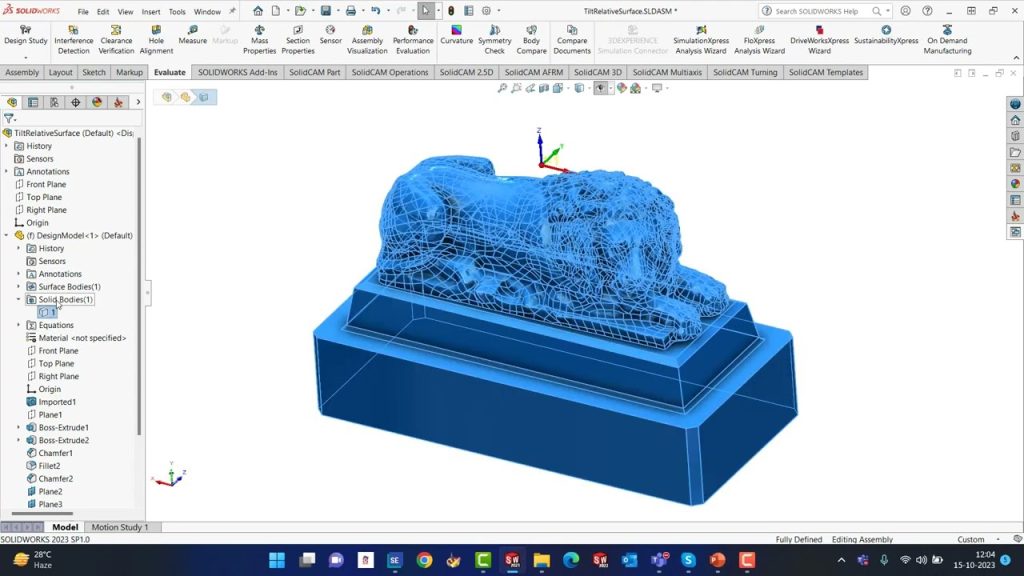

SolidCAM SolidWorks is a breakthrough in modern modeling. The merger of the two programs has made it possible to automate processes from the creation of parts and structures to their implementation. Now designers and technologists can work with one model in one program without switching to third-party resources.

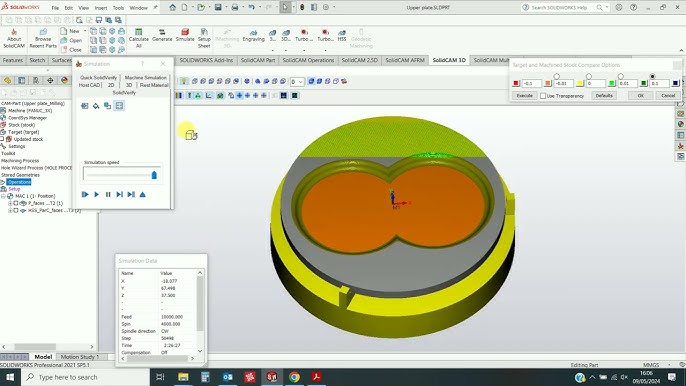

At the slightest change in the configuration of the created object, the program immediately recalculates the trajectory of the machine for its processing. Animation of the technology for creating a product can be immediately seen and adjusted. This allows you to reduce the design time and take into account all the technological nuances, as well as increase the service life of the cutting tool.

The main advantage of the resulting conglomerate is a multi-tasking and flexible tool for setting up optimal user parameters. The iMachining module, implemented in the SolidCAM system, supports all types of surface processing of products on modern turning and milling machines with numerical control, as well as their combinations.

SolidCAM is a well-known computer-aided manufacturing (CAM) software that integrates directly into various CAD systems, including SolidWorks. It provides tools for creating efficient and accurate tools for CNC machining operations. SolidCAM aims to optimize the process of turning a computer-generated design into a physical part by creating paths that control the movement of the CNC computer.

This system is a complete solution for the automation of metalworking production. Using the set of strategies provided by SolidCAM for machining, milling, machining, and unloading, technicians can quickly prepare a set of NC programs necessary to machine the product.

Key features of SolidCAM for SolidWorks include:

- Integration with SolidWorks: SolidCAM is tightly integrated with the SolidWorks platform, allowing users to work with both systems in a single window. This greatly simplifies the transfer of data between the various stages of design and machining.

- CAM functionality: SolidCAM offers a wide range of CAM modules for CNC machining of parts. These modules allow you to generate NC programs with high accuracy and efficiency.

- Modeling and design: With SolidCAM, users can easily create 3D models of parts, adjust their parameters and optimize them for CNC machining. The program also allows you to import ready-made models from

- SolidWorks for further machining.

- 3D milling and turning equipment: SolidCAM supports a wide range of 3D milling and turning operations, including various machining strategies and the use of various tools.

- Machining Management and Optimization: The program provides tools for machining process management, including parameter setting, toolpath optimization, and optimization of machining time and material consumption.

- Simulation and collision checking: SolidCAM allows users to simulate machining of parts, as well as check for collisions, which helps to avoid errors and reduce process setup time.

- Integration with equipment and standards: The program is compatible with a wide range of CNC machines from various manufacturers, as well as with industry standards and requirements, which provides convenience and flexibility in work.

- Application areas: SolidCAM for SolidWorks is used in various industries, including mechanical engineering, aviation, automotive, medical industry and others, where high precision and efficiency of production are required.

SolidCAM for SolidWorks is a modern and powerful software designed to optimize the process of designing and manufacturing parts and products. With its wide functionality, user-friendly interface and integration with the SolidWorks CAD platform, this program is an indispensable tool for engineers and manufacturing specialists who want to improve the productivity, quality and efficiency of their work. SolidCAM for SolidWorks will help you speed up the process of creating parts, avoid errors in processing, save time and money in production, and increase the competitiveness of your business.

Leave a Reply