Autodesk HSMWorks Ultimate 2023 Free Download

Autodesk HSMWorks Ultimate 2023 is a well-known and popular module for high-speed machining, which was specially developed for SolidWorks. The project itself was created from scratch and individually for SolidWorks, it is a logical continuation of the parametric environment of SolidWorks. If you consider yourself an experienced user, know the SolidWorks program inside and out, then with HSMWorks you will quickly find a common language, and you will be able to create high-quality machining programs without any problems, and it can really take about ten minutes.

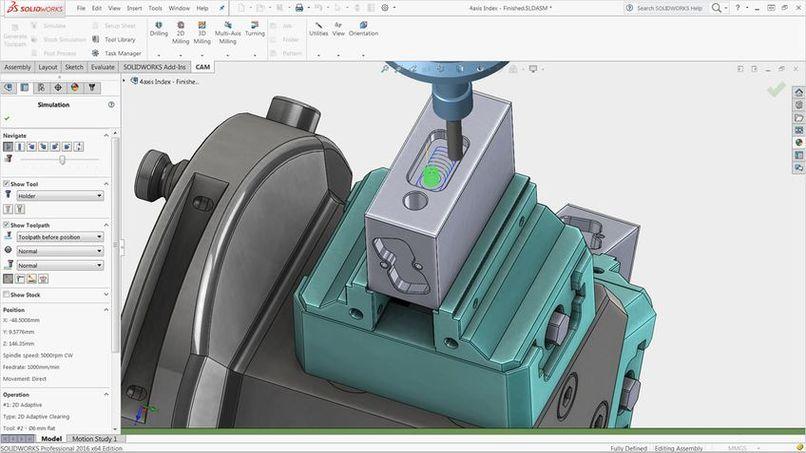

Seamless integration with SOLIDWORKS gives users access to all CAM capabilities directly in their familiar CAD environment. The program supports automatic updating of machining paths when changes are made to the CAD model, which significantly simplifies the design process and reduces the risk of errors.

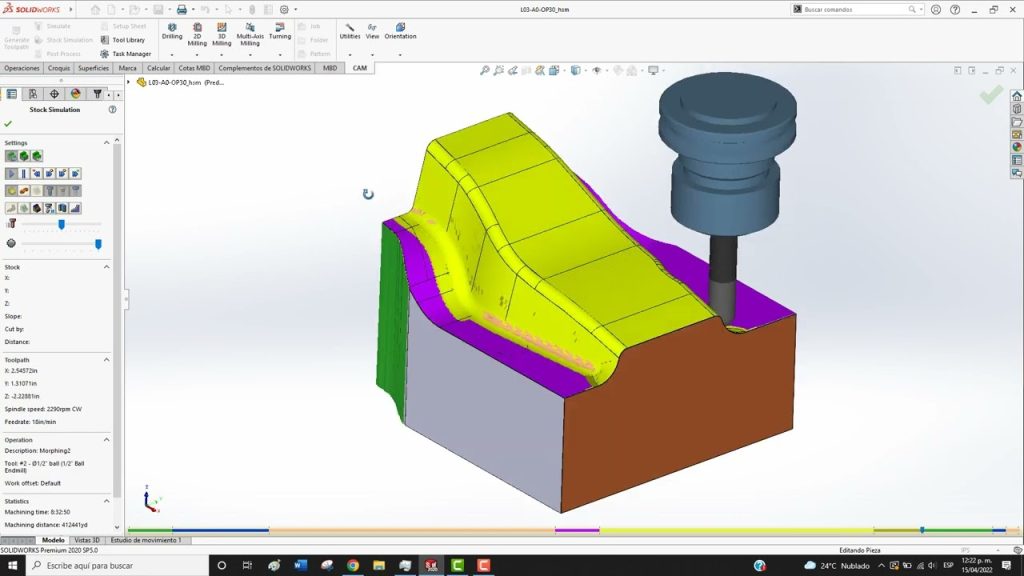

HSMWorks also provides machining simulation and collision checking tools, allowing users to optimize paths and prevent damage to the tool or workpiece. These tools will be important when working with expensive materials and complex parts, where accuracy and reliability are critical.

HSMWorks software is designed to create the smoothest toolpaths possible, resulting in reduced machining time, improved surface finish, reduced tool wear, and extended machine life. HSMWorks features innovative toolpath strategies such as adaptive clearing, which typically reduce roughing time by four times or more compared to conventional roughing, and increase tool life by up to ten times, depending on material hardness.

This program, HSMWorks, includes all the traditional machining strategies, including parallel, contour, pocket, scallop, radial, spiral, and pencil, familiar to most CAM users. HSMWorks extends these strategies by generating smooth, cohesive motions that reduce machining time and extend tool and machine life.

Autodesk HSMWorks Ultimate 2023 Features:

- Adaptive Clearing

- CAD/CAM Integration

- AnyCAD in Inventor

- Fast Toolpath Calculation Times

- 2.5-Axis Machining

- 3-Axis Milling and 3+2 Positioning

- Multi-Axis Operations

- Turning and Milling

- Waterjet, Plasma, and Laser Cutting

- Probing

- Tool Clamp Avoidance

- Shapes and Text Engraving

- Die-Place Machining

- Workpiece and Toolpath Modeling

- Editing NC Output

- Analysis Tools

Leave a Reply